The Walair Air separator

The Walair Air separator is suitable to split or separate a waste stream in a recycling installation in a heavy and a light fraction stream. For more info contact Walter Nihot

Applications

The Air separator is suitable to split or separate a waste stream in a heavy and a light fraction stream. The airseparator is mounted on a conveyor. The light fraction is picked-up and transported to a material separator with a rotary valve. In the material separator the air and the waste are separated. The waste is dropped down pressureless by the rotary valve.

Designs/Specifications

The Walair Air separator are made for a max fraction size of 500 mm when this fraction contain bigger sizes from paper and plastic is this no problem. The band width will be adjusted to the input capacity. The airseparator are made for conveyor width from 600 mm till 1600 mm. Max capacity from 2 tons till 12 tons an hour.

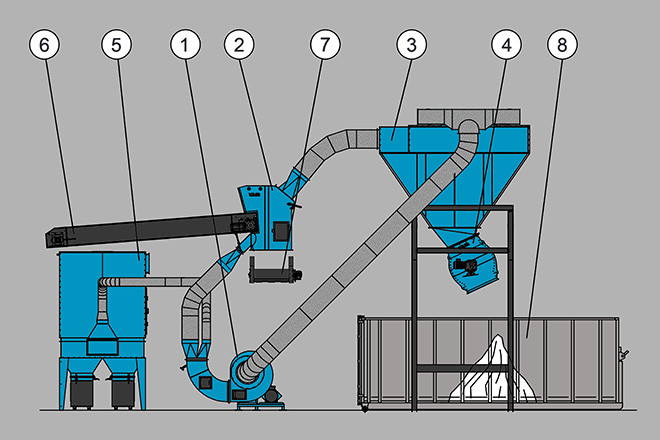

1. fan separator 2. airseparator with blowing mouth 3. material separator 4. rotary valve 5. Dustfilter 6. speed-up conveyor 7. heavy fraction conveyor 8. light fraction container or conveyor.

Operation principle of the Walair horizontal Air separator

Directly behind a fast running input conveyor (6), with and an effective width of 1200 mm., the Walair horizontal airseparator (2) is installed. The speed of the conveyor must be adjustable between 80-120 meter/min

The air separator is executed with an air transport duct. The separation of the light from the heavy materials takes place during the fall by means of an adjustable airstream. By means of a short trash chute the heavy fraction is transported to a conveyor (7), which is supplied by you or the customer.

The extracted light materials are transported by a round transport duct, to the Walair material separator (3).

The material separator is executed with an expansion room with trash chute and rotary valve (4). For the use of paper and film the rotary valve is specially construc¬ted by Walair.

The material separator is installed on a support in steel HEA. Under the material separator a rotary valve (4) is fitted, the rotary valve transports the fraction, pressureless to a conveyor or a container.

The air outlet opening of the material separator is, by means of a suction duct, connected to a Walair fan separator (1) .

The press outlet of the fan is, by means of an air regulation valve, connected to both the blow inlets of the air sieve. The air/dust outlet of the fan is, by means of a transport duct, connected to a dust filter (5). In this closed circuit the fractions are transported without touching the ducts or the fan. The chance to block or wear the system is reduced to a minimum.

It is possible to regulate the air capacity of the fan, as desired, by means of 2 air regulation valves within the suction duct of the fan. Another option is to connect the fan to a frequency regulator. Also the blow air to the airseparator and the capacity of the air/dust o¬utlet are adjustable by means of a regulation valve.

The advantage, to achieve a perfect separation of this system, is the principle of blowing and suction. The separation fan sucks 100%, blows 70/80% and transports 20/30%% of the air to a dust filter.

We note that the result of the separation depends on the dosage and distribution of the supplied fraction to the supplier conveyor.