The Walair Dust filter programm

Applications

Designs/Specifications

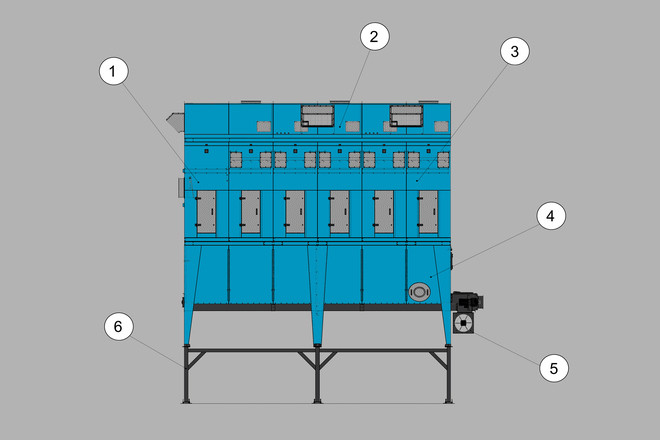

1. Blowing in section 2. Underpressure fan ‘s 3. Filter sections 4. Screw conveyor 5. Rotary valve 6. Frame filter

One of Walair best selling dust filters is the Walair HR dust filter.

This complete dust filter unit is entirely made up of standard panels, made of sendzimir galvanized sheet steel. The filter comes in semi-continuous and non-stop cleaning. Walair delivers this filter from an air capacity of 15,000 m3/h up to 80.000 m3/hour. The filter can be performed with one or more air inlet sections.

On top of the filter sections usually there is one filter section per HR exhaust fan.

The HR fans are high efficiency fans, where the return 20/25% higher is than with standard extraction fans. This results in significant energy savings.

When the desired exhaust capacity is known, we can make an exact energy savings calculation.

The dust which appears under the blowing in section and the filter section is collected in a collecting funnel. Under the funnel a screw conveyor is made. By means of the screw conveyor the dust is transported to the end of the filter, which features a rotary valve. The rotary valve transports the dust pressureless to a container The filter is placed on a steel structure, where the height of the floor can be adjusted.

If desired, the dust filter can be supplied in a continuous cleaning.

With this, 1 filter section is continuously closed by means of a jalousie valve, so this section is cleaned by means of activating the beat engine. Once this section is ready, the next will start, until each section has been done. This process repeats itself over and over on a preset amount of time, the length of time depends on the pollution.

Benefits of the Walair HR dust filter.

The Walair HR dust filter is a underpressure filter, whereby no material will be transported through the fan(s).

The underpressure fans are high efficiency fans, making significant energy savings. (20/25%)

The dust filter is very low in sound, because of the fans are built in the dust filter. If desired an extra sound insulation can be applied.

By the modular version the HR filter Walair can adjust the capacity of the filter for each customer independently. The eventual capacity extension can be adjusted at an existing filter.

To achieve even greater energy savings, the fans can be equipped with frequency regulators, with the regulator the desired exhaust capacity is continuously adjusted.

The dust filter can be linked to multiple exhaust pipes. Thereby it is possible, that when one of these pipes is not used, to quit. In this case, one or more exhaust fans are automatically shut off.

The screw transporter under the dust filter is made in our own production and our transport screws have a very large inlet and a diameter up to 500 mm and can be supplied to a length of 12 mtr.

The Walair HR dust filter meets the Atex standards and meets the most stringent dust emission and can be run with many options.