The Walair Rotating separator

Applications

Designs/Specifications

Walair delivers rotating separators from 5000 till 50.000 m3/hour.

The rotors of the separators are 950 or 1400 mm.

Of each diameter Walair makes three sizes.

De internal perforated plate can be adjusted at the size of the waste.

When you are interested in our rotating separators, ask for our more detailed information.

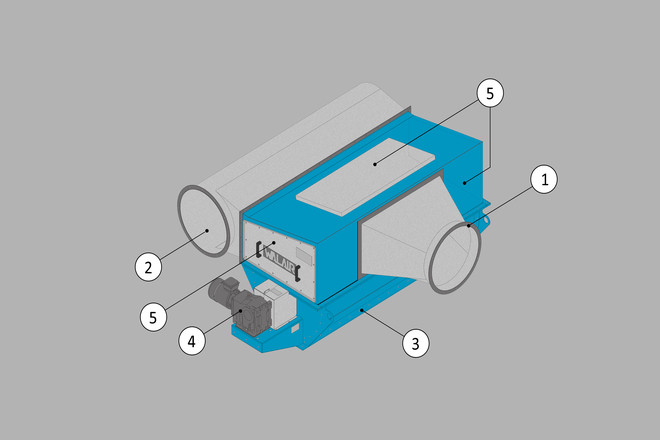

1. Air/waste inlet 2. Air outlet 3. Waste outlet 4. Power unit rotor 5. Inspection doors around separator.

Operation principle of the Walair Rotating separator.

The Walair rotating separator is applied in situations where waste, by means of air ducts, is transported. Through the application of the rotating separator, waste is separated from the air. The waste is disposed without pressure and the air in most cases is drained to a dust filter.

The Walair rotating separator is mostly used in situations where there is not much space available and is a good alternative to the aging cyclones and the well-known Walair material separator.

Operation

By means of air transport the waste is transported to the inlet No. 1 of the separator. In the separator, the air and waste go in a round separation room. Half of the surface of the room consists of perforated sheet or a screen (removable). In the room you’ll find a 6-bladed rotor with special vulcolan seals. The perforation of the separation room is adapted to the type of waste. The rotor is powered by means of a strong motor gearbox. No. 5 This engine ensures that the rotor makes between the 10 and 15 revolutions per minute. The exhausted air is drained by the perforated screen/hive to the air outlet of the separator no. 2. The vulcolan seals ensure that the perforated plate stays clean. The waste is transported to the waste exhaust by the rotating rotor no. 3 of the separator where it falls down the pressureless.

The Walair rotating separator can be both on negative pressure and overpressure in operation. The necessary transport fan can both be placed on the waste side or on the air side. The extracted air can go outside, or mostly drained to a dust filter.

Depending on the type of waste processed, the separator needs to be inspected and cleaned on a regular basis sometimes. To perform this fast and easy the Walair rotating separator is equipped with 3 large inspection doors No. 5 with spring balancers.

Benefits of the Walair Rotating separator.

Easy-to-access inspection doors.

Very heavy screening/hive which can be changed easily.

Separator can be used both on negative pressure as excess pressure.

Low power use.

Compact design.

Low noise.

Suitable for high air capacities.

Suitable for outdoor installation.

Extremely abrasion resistant vulcolan seals.