New compact air separator

Walair introduces a new product, the compact air separator. This compact unit is ready to use and is delivered at a mounted frame and can be placed directly behind a screen in a recycling installation.

The unit can be used to separate a waste fraction in two waste streams, one heavy and one light waste stream. For example, to separate a waste stream from building and demolition waste in two streams. One stream with stones and one stream with wood, paper and plastic.

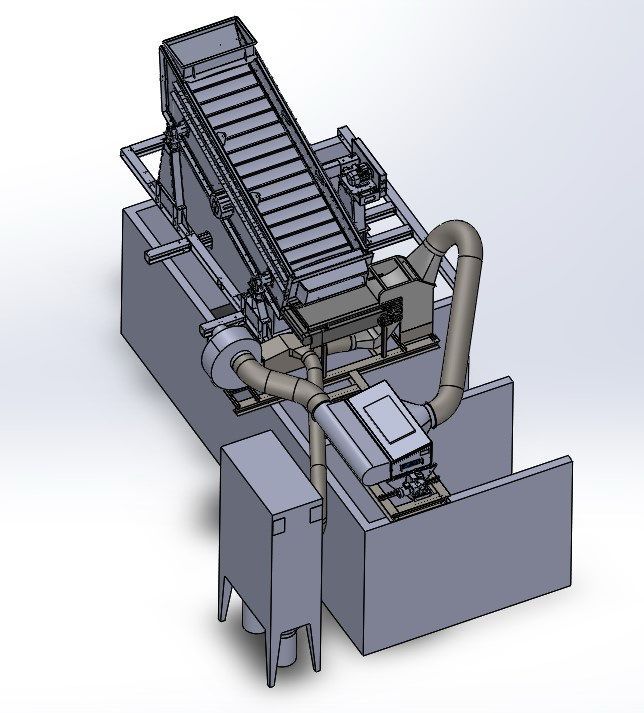

The unit is built with the following components. A fast running speed-up conveyor, a horizontal air separator, a fan separator and a special fabricated rotating material separator and all the necessary ductwork to connect all the components together. The fan separator can be connected to a dust filter, to make it possible to work dust free.

The unit is delivered in two sizes, one with an inlet width of 800 mm and one width 1000 mm. The max. fraction size which the units can handle is 150 mm.

The capacity depends of the m3 weight of the product. To give you an indication, with building and demolition waste, the units can handle between 20 and 30 ton/h.

Working principle

The Walair compact air separator can be put directly behind a screen. The screen has to remove the 0/10 mm fraction. Directly behind the screen the 10+ mm fraction is dropped on a high speed conveyor.

With this high speed conveyor the input material is spread and dosed and brought to a horizontal air separator.

The air separator consists of a separation room, a blowing mouth, an adjustable separation plate, and an adjustable extraction hood.

With a blowing airstream of 80% and an extraction of 100% in the extration hood, the heavy fraction is separated from the light fraction. The heavy fraction is dropped in a bunker or at a conveyor. The light fraction is extracted in the collection hood and transported with a round heavy duct to a rotating separator. In the rotating separator the transport air is removed from the light fraction and the light fraction is dropped pressureless in a waste bunker or at a conveyor. The Walair rotating separator is especially made for the recycling industry and equipped with big entrance doors and a oversized screen to separate the transport air from the light waste.

The air outlet of the material separator is connected with a small suction duct to a fan separator. The fan is only connected to the rotation separator (100%). The ventilator is connected to a separation bend with adjustable valve and two outlets. One dust/air outlet and one air outlet. The air dust outlet 20% can be connected to a dust filter and the air outlet 80% is connected with two flexible tubes to the blowing mouth of the air separator. The fan separator is equipped with an air regulation valve at the suction opening. With this valve the capacity can be adjusted. If wanted Walair can deliver the unit with a switchbox. The customer can install and start-up the unit.

With all the adjustable components the unit can be used for several types of waste. Interested in this new compact air separator? Contact or mail Walair separation systems.